About Us

Riverside Raw Materials Pvt. Ltd. is a part of Chicago Group of Companies located in Pakistan and USA.

We are in the business of providing Raw Materials to the Food and Beverage industry.

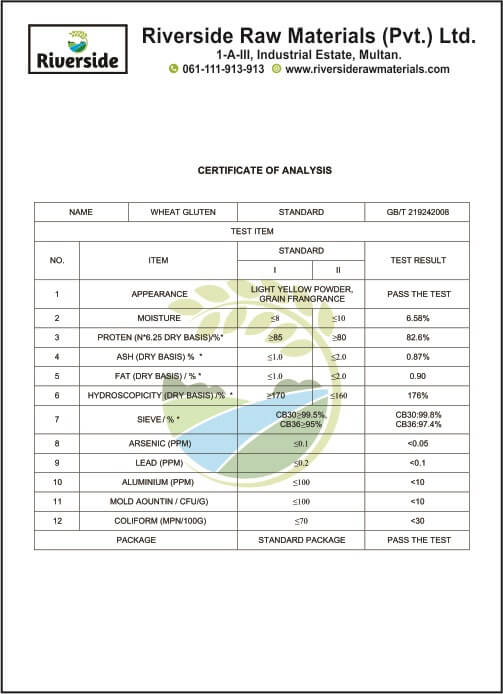

Lab Tests

Applications

Custard Recipe

Wheat Starch Recipe

Information Centre

- Properties

-

Film Forming

The film forming property of hydrated wheat gluten is a direct outcome of its viscoelasticity. Whenever carbon dioxide or water vapor forms internally in a gluten mass with sufficient pressure to partially overcome the elasticity, the gluten expands to a spongy cellular structure. In such structures, pockets or voids are created which are surrounded by a continuous protein phase to entrap and contain the gas or vapor.

This new shape and structure can then be rendered dimensionally stable by applying sufficient heat to cause the protein to denature or devitalize and set up irreversibly into a fixed moist gel structure or to a crisp fragile state, depending on final moisture content. The open texture of leavened breads; the suspension of solid particles such as fruit pieces or grains; and high fiber bread are examples of success due to the continuous phase of hydrated protein. Where the loading of added solid particles is greater than the strength possible from the flour used, “cripples” result. This is easily correctable by addition of wheat gluten to the flour base.

In addition to its film forming potential in food systems, cast or floated films of wheat gluten can be made. Glazing of meat patties is possible, and wheat gluten films in the form of sausage casing, tubes or shreds are recorded in the patent literature as the product of gluten “hot melt” techniques.Flavor

Properly produced and given reasonable care in storage, wheat gluten exhibits a flavor note variously described as “bland” or “slight cereal.” Wheat flavors enjoy wide acceptance and wheat gluten merges perfectly into all cereal-based products.

Blending with meats in various binding, adhesive and extension roles need not result in off-flavor notes, even at high percentage use levels.Blending of wheat gluten with other food proteins which do possess characteristic flavor notes can result in improved total flavor as, for example, when soy/wheat gluten blends are used for textured vegetable protein manufacture.

Low and acceptable flavor levels of wheat gluten are the result of careful selection of flours, good manufacturing procedures and proper storage at normal ambient temperatures.PH Effect

Since wheat gluten is a complex of proteins it has no sharp isoelectric (minimum solubility and dissociation) point. There is thus no readily discernible point at which the positive and negative charges exactly balance. Because glutenin is essentially insoluble in water over normal pH ranges, wheat gluten tends to reflect the isoelectric behavior of gliadin in pH/solubility properties.

When gliadin is separately examined for pH/solubility criteria, it displays minimum solubility over the pH range 6.0–9.0. It is in this range that the cohesive, extensible network of wheat gluten is strongest. It is important to note that wheat gluten becomes more soluble in acid or alkaline dispersions. (Some manufacturers utilize this effect to produce spray dried wheat gluten. The aqueous acetic acid or ammonia used is flashed off during the drying step, and the powdered material retains typical vital gluten characteristics.) PH manipulation may thus provide interesting property variations in wheat gluten containing foods.Thermosetting Properties

Although there are obvious exceptions such as gelatin, most hydrate able proteins undergo irreversible denaturation and insolubilization when heated to critical temperatures. Since hydrated wheat gluten is 25–30% protein and heat coagulates at roughly 85C, its utility in meat binding, canning, meat extenders and analogs, as well as in pastas and various other binding and shaping situations is obvious. Resistance to mushiness in steam table food service is a further benefit.

Viscoelasticity

The ability of wheat gluten to form a viscoelastic mass when fully hydrated sets it apart from all other commercially available vegetable proteins. Glutenin and gliadin, the two major protein components of wheat gluten, interact in an aqueous system to produce this viscoelastic property. Glutenin, the higher molecular weight protein fraction, contributes elasticity. Gliadin, of lower molecular weight, provides extensibility.

Water Absorption

Quality powdered wheat gluten rapidly absorbs about twice its weight of water. Since powdered vital wheat gluten has a protein content of 75–80% (dry basis), the hydrated version will drop to 25–27% protein at full hydration of about 65% moisture. Wheat gluten's capacity for holding water results in increased yield and extended shelf life in many food systems. The combination of speed of water absorption and the degree of viscoelasticity produced are evidence of “vitality.” Vital wheat gluten is a commonly used term.

Deliberate cooking of wet wheat gluten prior to drying results in “devitalized” wheat gluten. Devitalized wheat gluten is a popular substrate for hydrolysis in vegetable protein hydro lysate flavor manufacture. Disperse ability and speed of hydration of wheat gluten can vary with different processes of manufacture and are controllable. Suppliers should be consulted for special requirements. - Applications

-

Aquaculture

The farming of aquatic organisms, including fish and crustacea, is a rapidly expanding industry. Modern aquaculture increasingly depends on feeding to maximize production, and wheat gluten offers desirable properties to provide the binding needed for the pellet or granule forms of feed commonly used.

Wheat gluten’s water insolubility reduces pellet breakdown; its viscoelastic properties can provide a chewy texture preferable to an extremely hard pellet; it lends itself to extrusion and air incorporation, depending on whether surface or bottom feeding is desired; and it provides nutritional value.Bakery Products

No area of food processing enjoys greater benefits from wheat gluten usage than does the baking industry. Vital wheat gluten's unique viscoelastic properties improve dough strength, mixing tolerance and handling properties. Its film-forming ability provides gas retention and controlled expansion for improved volume, uniformity and texture; its thermosetting properties contribute necessary structural rigidity and bite characteristics; and its water absorption capacity improves baked product yield, softness and shelf-life.

Vital wheat gluten is commonly used in hard rolls and multigrain, high-fiber and other specialty breads at levels ranging (flour basis) from 2% to as high as 10%. If used at approximately 2% in pre sliced hamburger and hot dog buns, gluten improves strength of the hinge and provides desirable crust characteristics when the buns are stored in a steamer.

Yeast-raised donuts have greater volume and increased strength during subsequent glazing; and, in virtually all baking applications, wheat gluten's natural flavor enhances consumer acceptability.Breading, Batters, Coatings & Flavors

Adhesion of batter crusts and breading’s to fried foods has always been a quality problem, particularly in frozen products. Pre dusting of such food portions with wheat gluten significantly improves adhesion, reduces cooking loss and enhances appearance.When wheat gluten is added to a batter mix, the film formation reduces liquid loss and also produces crisp, appetizing surfaces. Vital wheat gluten has also been used in coating dry roasted nuts, providing adhesion for the salt and other seasonings. Acid hydrolysis of wheat gluten has been used to prepare hydrolyzed vegetable proteins as flavor enhancers.

Breakfast Cereals

Wheat gluten-fortified breakfast cereals have been widely accepted by consumers, because they are very flavorful and nutritious, especially when consumed with milk. Wheat gluten provides not only the protein desired for nutritional claims but also helps bind any vitamin-mineral enrichment components to the cereal or grain berry in processing and contributes to the strength of flaked cereals.

Cheese Analogues & Pizza

Vital wheat gluten’s viscoelastic properties can be used in preparing synthetic cheese with the characteristic texture and eating quality of natural cheese. Recent studies sponsored by the International Wheat Gluten Association have shown that vital wheat gluten, alone or in combination with soy protein, can be used to replace approximately 30% of the more expensive sodium caseinate used in imitation American and mozzarella cheese products.

Wheat gluten can also be used to strengthen pizza crust, making it possible to produce both thin and thick crusts from the same flour. The incorporation of gluten provides crust body and chewiness and reduces moisture transfer from the sauce to the crust. Typical use levels (flour basis) range from 1 to 2%.Meat, Fish, Poultry and Surimi Based Products

The unique adhesive, cohesive and film-forming characteristics of hydrated vital wheat gluten and its thermosetting properties form the basis of various types of applications in meat, fish, and poultry products.

Wheat gluten is very effective in binding meat chunks or trimmings together to form restructured steaks or chops and may be applied simply by dusting the meat pieces with dry gluten. It is an excellent binder in poultry rolls, canned “integral” hams and other nonspecific loaf-type products where it also improves slicing characteristics and minimizes cooking losses during processing and/or preparation.

Vital wheat gluten is also useful in extending ground meat patties and as a protein binder in sausages and other meat emulsion products. When hydrated, it can be extruded, texturized by expansion, drawn into fibers and spun, or cast into films. Simulated meat products may be produced for a variety of applications, and wheat gluten has been used to produce meat, poultry and seafood analogues, vegetarian meat-like patties, and even artificial caviar.

Textured protein products fabricated from wheat gluten and soy/wheat gluten blends have highly acceptable flavor and structural integrity in the finished product. A soy/wheat gluten textured meat extender has approval for school lunch programs in the U.S. Other governmental regulations should be checked to assure the full, proper and effective use of wheat gluten.

Surimi is a Japanese term for mechanically deboned, minced fish flesh that has been repeatedly washed with chilled water until it is essentially odorless and colorless. The protein in surimi gels upon heating produces an elastic, chewy texture which is especially desirable in making crab, scallop, shrimp and other seafood analogues.

The incorporation of about 2.0% vital wheat gluten into surimi enhances gel strength and reduces the development of undesirable rubbery texture after frozen storage. Vital wheat gluten’s high water-holding capacity and lower cost than commonly used egg white also provide improved economics.Milling and Flour Fortification

Perhaps the most fundamental use of vital wheat gluten is in the adjustment of flour protein level, by either the flour miller of or the baker. Many millers use gluten to streamline production and supplement lower-protein local wheat’s to meet bakery flour standards. As a natural additive, there are no limits to the amounts that can be used in achieving product quality objectives.

Considerable research continues to be devoted to create satisfactory bakery products involving composite or non-wheat flour for application in third world countries. Millet, cassava and maize are some of the grains which can be used along with wheat gluten to produce satisfactory bakery products.Nutritional Snacks

The charge of "junk" foods or "empty" calories often leveled at snack foods should prompt fabricators of snacks to examine wheat gluten closely as a worthwhile ingredient. Many international examples of such wheat gluten based snacks are now being marketed, including gluten balls in Europe, vegetarian items in the United States, Yachi-fu cakes in Japan, fried gluten items in China and wafers of 30-45% wheat gluten content in Australia. In extruded snacks, wheat gluten provides nutritional value, crispness and desired texture. Use levels are generally 1-2%.

Pasta

Although durum wheat is preferred for the production of pasta because of its particular rheological properties and color, other more available flours can be used effectively if wheat gluten is added. Gluten addition can reduce cooking loss and stickiness in cooked pasta, provide good cooked firmness, increase resistance to breakage, and improve heat tolerance in canned retorted products.

High-protein pasta formulations using vital wheat gluten in combination with soy protein and lactalbumin have been developed; they satisfy the protein quality (P.E.R.) requirements of the U.S. Type A School Lunch Program.Personal Care Products

Wheat Gluten offers a wide range of properties that are perfect for use in cosmetics and personal care products.

Pet Foods

Significant quantities of vital wheat gluten are used by the pet food industry. The usage may be in preparing simulated meat for canned pet food or in both canned and intermediate moisture-type products where the water absorption and fat binding properties of wheat gluten improves yields and quality. In dry dog biscuits, incorporating gluten into the dough before baking can improve resistance to breaking during packaging and shipping. Because it is a great source of protein, wheat gluten can significantly contribute to nutritional labeling claims.

Tortillas

The popularity of flour tortillas has increased greatly in the past decade. The addition of about 2.5% vital wheat gluten in tortilla formulations (flour basis) improves the pliability of tortilla dough’s and significantly reduces cracking and breaking of problems.